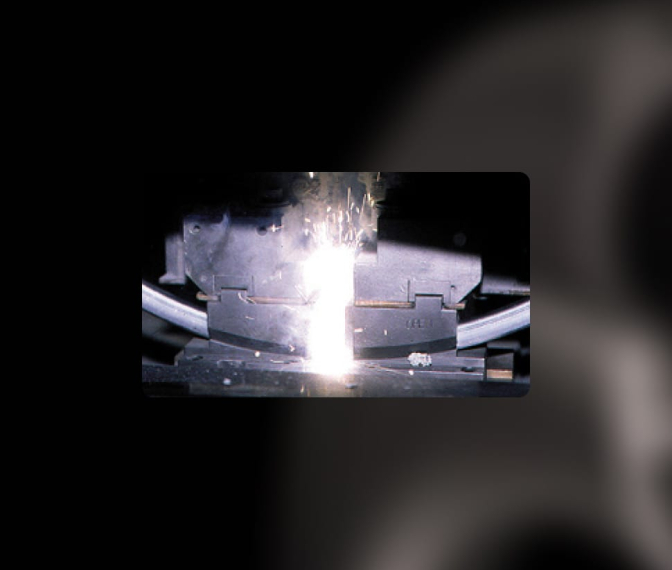

Developed in close collaboration with Mavic Team riders, the Deemax Park 29 is the close cousin to the Deemax Enduro SL and DH, but built to withstand the heaviest impacts and for landing big jumps or double jumps. It's laced with 32 J-Bend spokes in swaged steel, and its rim walls feature PFP (Pinch Flat Protection) technology to greatly reduce the risk of punctures.

The Deemax Park 29 stands out for its versatility. Freeride, DH, Dirt, Enduro—it can do it all, especially because it's available in 26" and 27.5" sizes, in addition to 29”, making it compatible with all setups and all bikes, including those with different front and rear wheel standards.

This wheel has been designed with Mavic’s spirit of repairability and durability, to make life as easy as possible and keep exceptional equipment rolling for as long as possible. The J-Bend spokes can be repaired quickly and easily, and each wheel set comes with two replacement spokes for real peace of mind (extras are available for purchase). The ID360 hubs require very little maintenance, are made from standard Mavic parts and can be easily dismantled without tools, too.

Versatile, easy to maintain and particularly hard-wearing, the Deemax Park 29 wheel will take the most violent shocks without flinching. What about you?

The Deemax Park 29 stands out for its versatility. Freeride, DH, Dirt, Enduro—it can do it all, especially because it's available in 26" and 27.5" sizes, in addition to 29”, making it compatible with all setups and all bikes, including those with different front and rear wheel standards.

This wheel has been designed with Mavic’s spirit of repairability and durability, to make life as easy as possible and keep exceptional equipment rolling for as long as possible. The J-Bend spokes can be repaired quickly and easily, and each wheel set comes with two replacement spokes for real peace of mind (extras are available for purchase). The ID360 hubs require very little maintenance, are made from standard Mavic parts and can be easily dismantled without tools, too.

Versatile, easy to maintain and particularly hard-wearing, the Deemax Park 29 wheel will take the most violent shocks without flinching. What about you?

Main features

Commit with confidence on any terrain

The 32 J-bend spokes offer excellent resistance against the most violent impacts and abuses

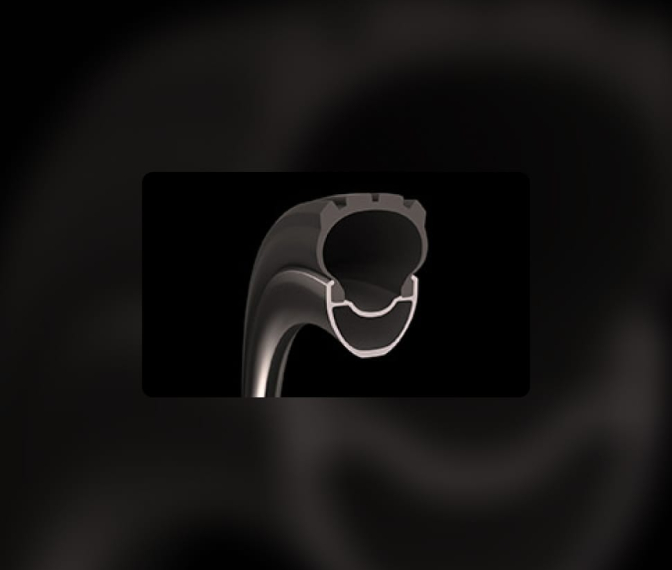

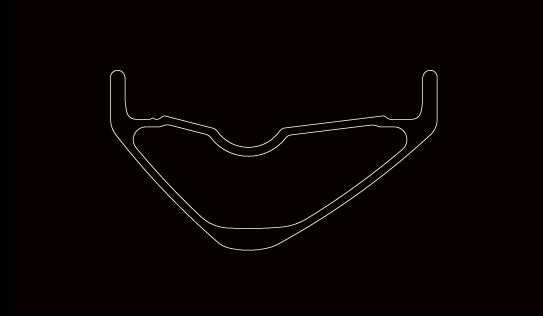

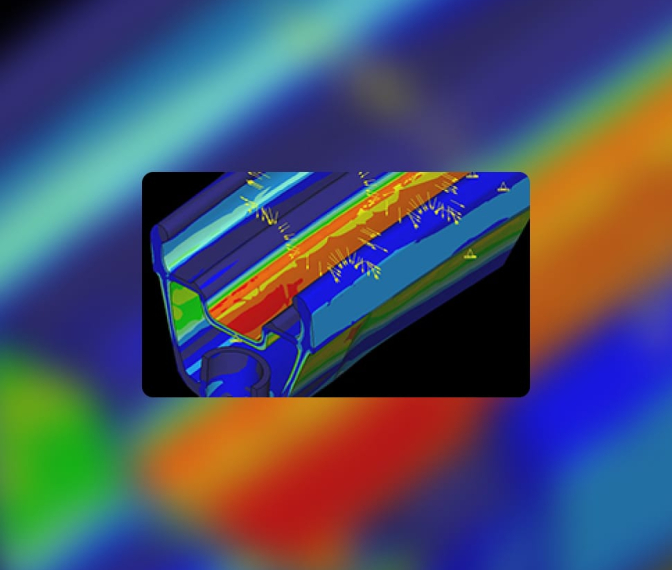

Reduce the risk of flat tires thanks to PFP (Pinch Flat Protection) rim walls

Reduce the risk of flat tires thanks to PFP (Pinch Flat Protection) rim walls

An adapted wheel to every Gravity practices

Adapted to multiple practices, Freeride, DH, Dirt jump, Enduro

Available in 26’’,27.5’’ et 29’’

Rear wheel available in Boost (12x148) and Super-Boost (12x157)

Front wheel available in 20x110 Boost and 15X110 Boost

Available in 26’’,27.5’’ et 29’’

Rear wheel available in Boost (12x148) and Super-Boost (12x157)

Front wheel available in 20x110 Boost and 15X110 Boost

Easy to service and fix

Quick and easy to fix thanks to J-Bend spokes

Two replacement spokes delivered with every wheelset

Low maintenance ID360 hubs made of standard Mavic parts and easily removable without tools

Two replacement spokes delivered with every wheelset

Low maintenance ID360 hubs made of standard Mavic parts and easily removable without tools

Specifications

Key technology

These product categories might interest you

DEEMAX PARK 29