Don't miss

High-performance road shoe with comfortable fit, Boa® L6 tightening system and efficient power transfer. Made in Italy

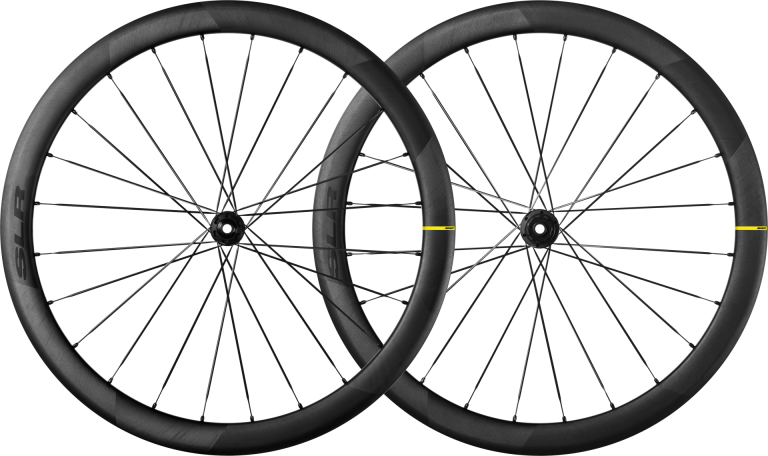

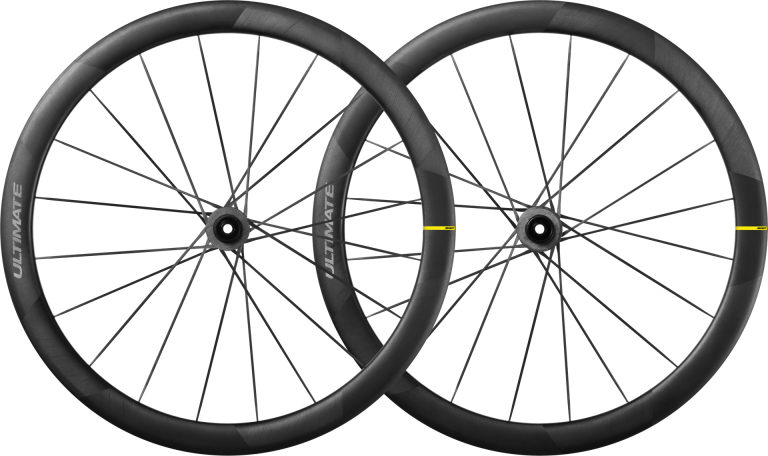

- Road

Guaranteed efficiency, no matter where it takes you

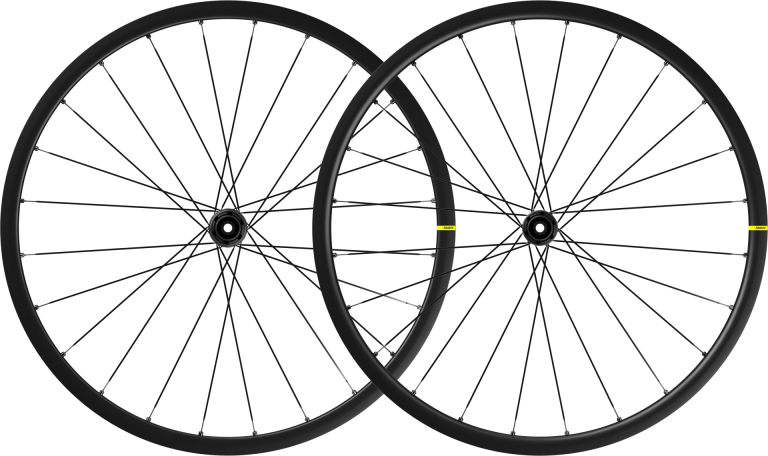

Discover our products for the road - Gravel

Performance doesn’t mind getting dirty

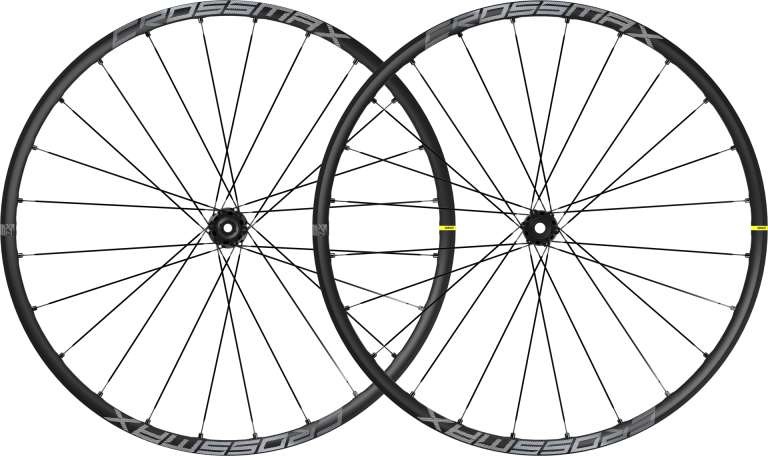

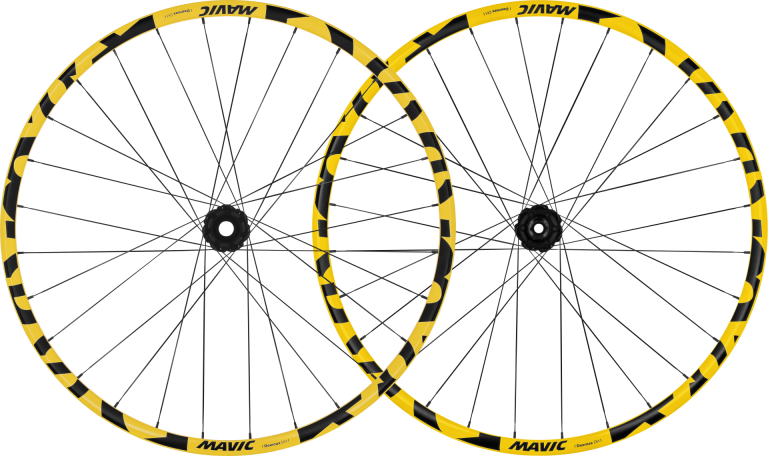

Discover our products for Gravel - Mountain Bike

Mastering technical terrain, wilderness and everything in between

Discover our mountain bike products - Track

Precision and speed for the demands of the velodrome

Discover our track products - Urban Bike/City Bike

Uban performance, inspired aesthetics

Discover our Urban products

Stories on wheels

WE OPEN THE WAY FOR ALL CYCLISTS

We support all cyclists in their quest for gentle mobility and performance.

IN TOWN, ON YOUR DAILY COMMUTEFind out more

IN DH, IN YOUR QUEST FOR THRILLSFind out more

ON THE ROAD, RIDING FOR PERFORMANCEFind out more

IN GRAVEL, NEED TO GET AWAY FROM IT ALL?Find out more

EXPERIENCE THE TRACKFind out more